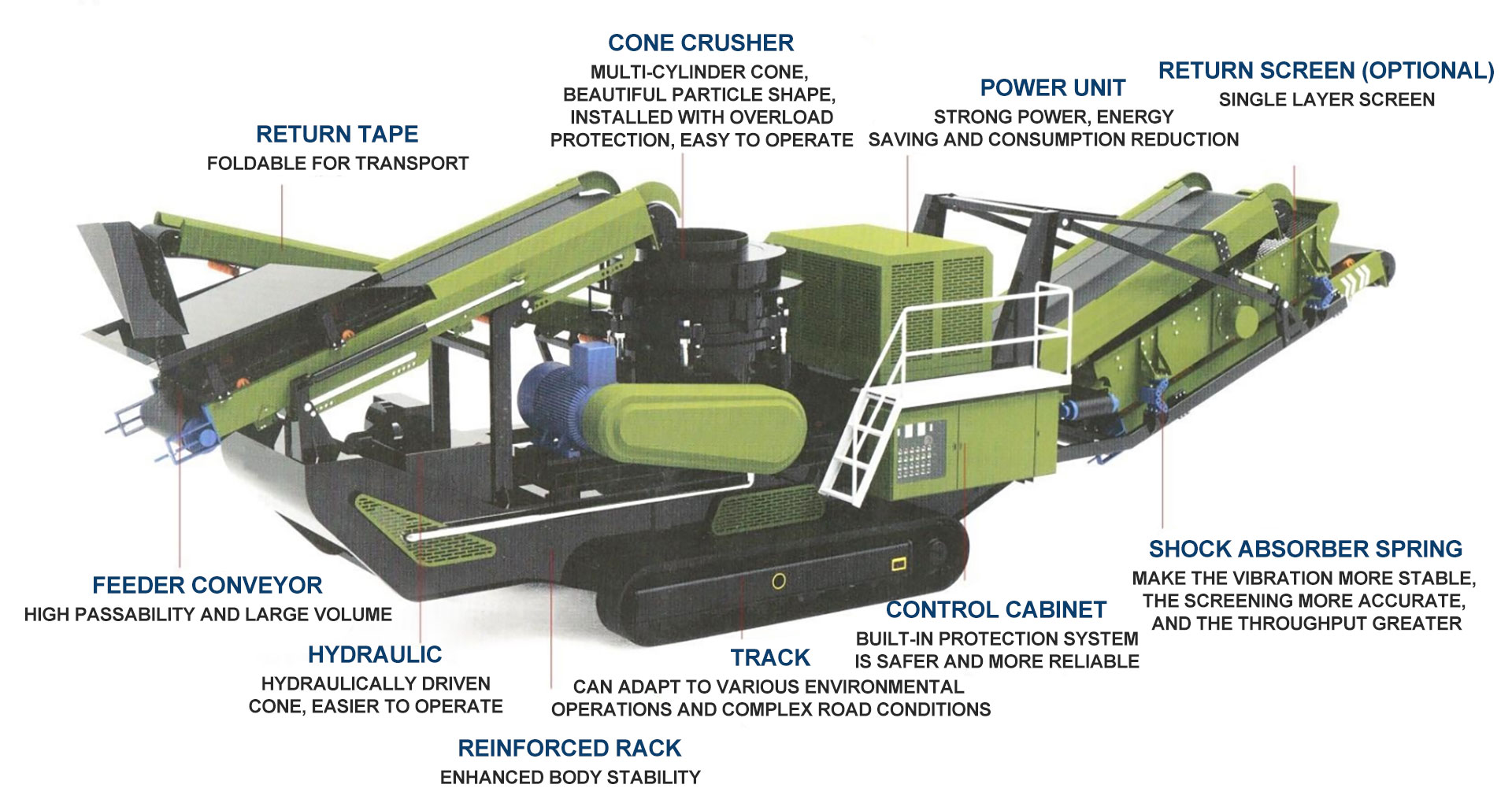

Excellent Cone Crusher

Excellent Cone Crusher Advanced Lubrication System

Advanced Lubrication System Widely Applicable Scenarios

Widely Applicable Scenarios Quick Transition

Quick TransitionThis product is suitable for crushing raw materials in themetallurgical, construction, road building, chemical, and silicateindustries.It is divided into many models based on differentcrushing principles and product particle sizes. Crushers arewidely used in various sectors such as mining, smelting, buildingmaterials, highways, railways, water conservancy, and chemicalindustries, cone crusher has a large crushing ratio, highefficiency,low energy consumption, and uniform product particlesize, suitable for medium and fine crushing of various ores androcks.

| Product Model | EX-HP300 | Processing Capacity(t/h) | 150-230 | Main Power(kW) | 250 | |||

| Total Power(kW) | 298 | Feed Opening Size(mm) | φ1078 | Suggested Feeding Size(mm) | <200 | |||

| Feeding Belt(kW) | 11 | Main Belt(kW) | 15 | Vibration Hanging Screen(kW) | 6 | |||

| Finished Belt(kW) | 7.5 | Transition Zone(kW) | 3 | Return Belt(kW) | 5.5 | |||

| Hopper Capacity(m³) | 5 | Total Weight(t) | 48 | Equipment Dimensions (LXW×H)(mm) | 16800×3650×3950 | |||