Engineering Machinery Maintenance: Prolonging the Life of Changyu Equipment

Engineering machinery operates under some of the most demanding conditions in modern industry. In construction, mining, demolition, and infrastructure development, equipment is exposed to heavy loads, continuous vibration, dust, moisture, and extreme temperatures. Proper maintenance is therefore not only essential for safe operation but also critical to maximizing equipment lifespan and protecting long-term investment. Jiangyin Changyu Machinery Co., Ltd. designs its equipment for durability and reliability, and with the right maintenance practices, Changyu machinery can deliver consistent performance for many years. Effective maintenance begins with a clear understanding of operating conditions. Different applications—such as rock breaking, steel cutting, mobile crushing, or ground compaction—place different stresses on machinery. Operators should always select the correct Changyu equipment and attachments for the task at hand and avoid overloading or misuse. Following recommended operating parameters helps prevent premature wear and ensures that key components such as hydraulic systems, structural frames, and wear parts perform as intended.

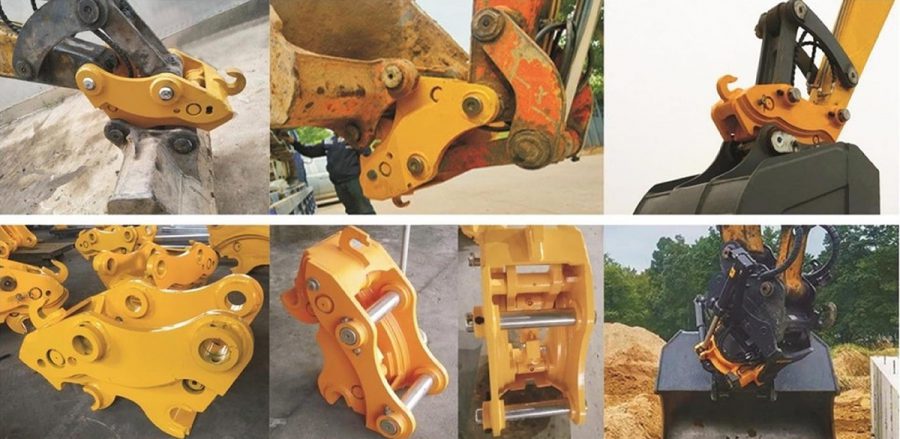

Routine inspection is one of the most important aspects of machinery maintenance. Daily visual checks allow operators to identify early signs of wear, leakage, or damage before they develop into major issues. For Changyu breakers, hydraulic shears, vibrating rammers, and mobile crushing stations, inspections should focus on hydraulic hoses, fittings, bolts, pins, and structural welds. Detecting loose fasteners, oil leaks, or abnormal wear early reduces the risk of sudden failures and costly downtime. Hydraulic system maintenance plays a central role in prolonging the life of Changyu equipment. Hydraulic components are the driving force behind most engineering machinery, and clean, properly pressurized oil is essential for smooth operation. Operators should regularly check oil levels, monitor oil temperature, and replace hydraulic filters according to maintenance schedules. Contaminated or degraded hydraulic oil can cause accelerated wear on pumps, valves, and cylinders, reducing efficiency and shortening equipment life. Maintaining a clean hydraulic system ensures stable power output and protects both the attachment and the carrier machine.

Lubrication is another critical factor in maintaining long-term performance. Changyu machinery includes multiple moving parts that rely on proper lubrication to reduce friction and wear. Pins, bushings, bearings, and joints should be lubricated at specified intervals using recommended lubricants. Proper lubrication not only minimizes mechanical wear but also helps prevent corrosion, especially in harsh working environments such as coastal areas or underground operations. Consistent lubrication significantly extends service life and keeps machinery operating smoothly. Wear parts require special attention, as they are designed to absorb the most stress during operation. Components such as breaker chisels, shear blades, crushing teeth, and rammer plates should be inspected regularly for wear and deformation. Replacing worn parts at the right time prevents secondary damage to major structural components. Changyu designs its wear parts for easy replacement, allowing maintenance tasks to be completed efficiently without extended downtime. Using original or approved replacement parts ensures proper fit and maintains equipment performance.

Correct operation also plays a vital role in reducing maintenance needs. Even the most robust machinery can suffer damage if operated improperly. Changyu recommends that operators receive proper training to understand machine behavior, load limits, and safe operating techniques. Smooth operation, controlled movements, and avoiding sudden impacts help protect hydraulic systems and structural components. Skilled operation not only improves safety but also significantly reduces long-term maintenance costs. Environmental conditions should also be considered in maintenance planning. Dusty environments can accelerate wear and clog filters, while wet or muddy conditions increase the risk of corrosion. After working in harsh conditions, Changyu equipment should be cleaned thoroughly to remove debris and moisture. Regular cleaning prevents contamination, improves heat dissipation, and allows for more accurate inspections. Simple practices such as cleaning cooling systems and removing accumulated material can greatly extend equipment life.

Jiangyin Changyu Machinery Co., Ltd. builds its equipment to meet high international standards, using advanced manufacturing processes and durable materials. When combined with proper maintenance practices, Changyu machinery becomes a long-term partner in construction, mining, and infrastructure development. By focusing on routine inspections, hydraulic care, lubrication, correct operation, and timely replacement of wear parts, operators can significantly prolong the life of their Changyu equipment. In an industry where reliability and efficiency are essential, effective maintenance is the key to sustained performance. With the right care and professional support, Changyu equipment continues to deliver strength, precision, and dependability—project after project—helping customers build safely, efficiently, and with confidence well into the future.